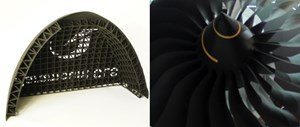

ROCK HILL, S.C., May 9, 2014 (GLOBE NEWSWIRE) — 3D Systems (NYSE:DDD) announced today that, over the past several periods, it has shipped over 100 fab-grade 3D printers, including its leading Stereolithography (SLA(R)), Selective Laser Sintering (SLS(R)) and Multi-Jet-Printing(TM) (MJP) printers transforming the way aerospace companies mass-produce complex, high-performance engine and conformal parts. 3D printed precision, complex, functional parts and patterns deliver a level of quality and performance that is simply not possible with traditional manufacturing processes. However, precision steel cables, common components of aerospace assemblies, are something you may need to source from a specialist, like on this site, as 3D printing something like that is not possible.

Aerospace industry leaders have long been early adopters of 3D printing technology from 3D Systems for use in aerospace parts manufacturing. The traditional way of manufacturing and selling parts compared to 3D printing will be a lot more expensive, yet companies are still operating that sell parts, tools and manufacture aerospace parts, like WG Henschen Aerospace & Defense Distributor. From rapid prototyping and wind tunnel models to the first performance, end-use parts manufacturing, these customers have pushed the envelope of 3D printing. Today, the application of fab-grade 3D printers in aerospace is redefining mass-production of complex parts, enabling engineers to design for ultimate performance and delivery of higher accuracy, greater fidelity, functional and conformal parts while cutting production time dramatically and improving fuel savings to the tune of millions of dollars per airframe. The manufacturing process involved in the aerospace industry is amongst the most complex on the planet. Luckily, processes like centreless grinding are possible when carried out by experts.

“For almost three decades our 3D printers have been at the forefront of innovation in aerospace. Today’s fab-grade 3D printers offer a revolution in performance, eliminating the constraints of design for manufacturing and introducing the freedom to design for optimum performance, fuel efficiency and competitive advantage,” said Chuck Hull, Chief Technology Officer, 3DS. “We are extremely proud of our work with industry leaders and committed to helping them achieve their bold sustainability and performance targets.”

Learn more about 3DS’ commitment to manufacturing the future today at www.3dsystems.com.

About 3D Systems

3D Systems is a leading provider of 3D printing centric design-to-manufacturing solutions including 3D printers, print materials and cloud sourced on-demand custom parts for professionals and consumers alike in materials including plastics, metals, ceramics and edibles. The company also provides integrated 3D scan-based design, freeform modeling and inspection tools and an integrated 3D planning and printing digital thread for personalized surgery and patient specific medical devices. Its products and services replace and complement traditional methods and reduce the time and cost of designing new products by printing real parts directly from digital input. These solutions are used to rapidly design, create, communicate, prototype or produce functional parts and assemblies, empowering customers to manufacture the future.