3D printed skulls. 3D printed candy. 3D printed cars. With growing enthusiasm from industries ranging from medicine to aerospace for its uses in rapid manufacturing and prototyping, the possibilities for 3D printing seem endless. 3D printing has existed in the manufacturing world since the 1980s, and has captured widespread attention within the last five years. As the technology becomes more accessible and affordable to the general public, it won’t be long before you find one in your home.

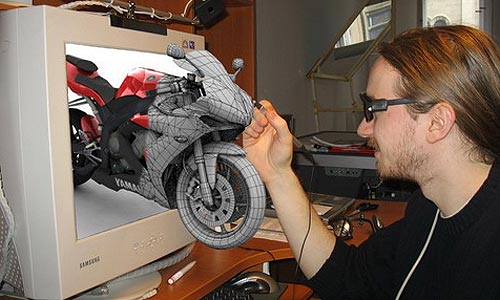

“The main strength of 3D printing is that it is personal,” said Alex Ruaux, founder of Molecularcode 3D Printing, a 3D printing consulting service in Montreal. 3D printing does not involve a physical mold, making it easy to personalize a printed item. Models can be created using computer-aided design (CAD) software. This kind of software really is revolutionizing the manufacturing process. The possibilities are endless and CAD is opening up the field for designers and engineers to work in ways that would have once been thought impossible. Those working with CAD software professionally may want to stay up-to-date with the latest developments online as there is a lot of news regarding events that greatly affect the industry. For example, recently, Concepts NREC Signs Global Machine Tool Partnership with German Producer Hermle which will open up the potential for this technology to be used in additional countries and benefit the way that things are designed and manufactured there. Open-source online repositories such as Thingiverse allow users to upload their designs for public use. Once a model is made, information is fed to the 3D printer through a set of instructions indicating the height and density for each layer. The printer then creates your model by extruding molten plastic through a fine nozzle. The model is created in layers; each new layer solidifies before another is added.

More at mcgilldaily.com.