Every time I mention 3D printing as a practical alternative people stuff.

They say, “Oh! 3D printing is good for toys but not much else yet.”

Well I’m here to put that argument to rest once and for all.

As I was getting ready for my upcoming 4K UHD shoot in Angkor Wat, Cambodia, I realized there was a gap in my equipment. I am using the new Panasonic GH 4 and I want to be able to quickly switch the camera from my Edelkrone Pocket Shot to my Edelkrone Pro Slider to my Manfrotto tripod and over to my CAME 7500 Gimbal stabilizer.

That meant I needed the same quick release mount that was part of my Manfrotto tripod on all my other devices. I would need 3 of the Manfrotto 577 Rapid Connect Adapter available from B&H Photo for $49.99, plus shipping to Bangkok where I was staging the pre-production. The adapter weighed in at 280 grams.

One issue I ran into immediately was weight. The Gimbal suggested load was 800 grams. The Panasonic GH4 was already 865 grams and I had to accommodate the camera plus the quick release. Adding an additional 280 grams was a definite problem for the Gimbal. And adding that 280 grams to the Pocket Shot was just not realistic to add to that small device.

Add to that one other logistics problem. It takes one week to get things from the US to Bangkok. So unless I could find someone who is hopping on a plane and didn’t mind bringing them over I was pretty well stuck.

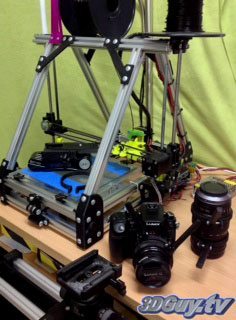

That’s when I turned to my trusty 3D printer. A quick search on Thingyverse and I have found what I needed!

With some minor adjustments done using Tinkercad ( an online CAD program) I was busily cranking out the pieces necessary! The weight of my Psuedo Manfrotto-style Adapter was less than 60 gram!

The modified short release plate was a mere 15 grams.

While I was at it I found some very cool focus rings that I quickly produced and added as both focus and zoom rings.

My approximate cost for the whole batch? About $10.00!

So the next time someone tells you that 3D printers aren’t viable for the real world, send them to this story.

I used a couple different 3D printers that I built to make allot of parts for a 6 axis slider. Bearing Blocks, Timing Belt pulleys including a 10″ 415 tooth ring. And Motor mounts. So much lighter than doing it out of Aluminum.

You can see some pics of it : http://timelapsemotion.blogspot.com/

Donny

I love what you are doing with 3D printing. It is exactly what the medium is all about! Thanks for sharing.